Product Description

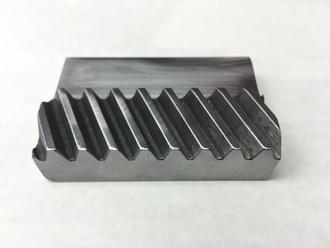

Gear And Rack Pinion

Product Description

| Model number | M1-M12 |

| Material | Brass, C45 steel,Stainless steel,Copper,POM,Aluminum,Alloy and so on |

| Surface treatment | Zinc plated, Nickel plated, Passivation, Oxidation, Anodization, Geomet, Dacromet, Black Oxide, Phosphatizing, Powder Coating and Electrophoresis, etc |

| Standard | ISO, DIN, ANSI, JIS, BS and Non-standard. |

| Precision | DIN6,DIN7,DIN8,DIN9. |

| Teeth treatment | Hardened,Milled or Ground |

| Tolerance | 0.001mm-0.01mm-0.1mm |

| Finish | shot/sand blast, heat treatment, annealing, tempering, polishing, anodizing, zinc-plated |

Packaging & Shipping

Packaging Details:

1)Sample order packing by paper carton for saving freight charge;

2)bulk order sent by sea will be packed by film and wooden carton.

3) as customer’s requirements.

Company Profile

Company Information:

ZheJiang SAIR MECHANICAL XIHU (WEST LAKE) DIS. CO.,LTD

ZheJiang Sair Mechanical Xihu (West Lake) Dis. Co., Ltd, which is mainly responsible for the production, 1 of the largest linear guide and ball screw manufacturer in China. With strong technical strength, advanced production equipments, and perfect after-sale services, our company is the leading precision machinery manufacturer, which have research and development, manufacturing, sales, service all in one. Our high-quality products are not only popular all over the country, but also exported to Europe, Americas, Southeast Asia, Africa etc. , totally more than 70 countries globally. Our products have good performance and are highly trusted and admired by all the domestic & overseas customers.

FAQ

1. Q: How about the quality of your product?

A: 100% inspection during production.

Our products are certified to ISO9001-2008 international quality standards.

2. Q: What’s the delivery time?

A: For custom order, within 2000 meters,

Production time is 15days after confirmed every details.

3. Q: What’s your packing?

A: Our Normal packing is bulking in PE bag, and then into plywood Cartons.

We also can pack products according to your requirement.

4. Q: What about the warranty?

A: We are very confident in our products,

and we pack them very well to make sure the goods in well protection.

5.Q: Could you send me your catalogue and price list?

A: As we have more than hundreds of products,

it is really too hard to send all of catalogue and price list for you.

Please inform us the style you interested, we can offer the pricelist for your reference.

6.Q:There are a lot of companies which export bearings, why do you choose us?

A: As we are a genuine linear guide supplier since 2011.and we are really factory, you need not pay the profit for middlemen.

so we can offer you the lowest and competitive price .

Thanks for your valuable time 🙂

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Samples: |

US$ 6/Piece

1 Piece(Min.Order) | Order Sample not free

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the design of the helical gear rack affect its performance?

The design of the helical gear rack plays a crucial role in determining its performance characteristics. Here’s a detailed explanation of how different design aspects of the helical gear rack affect its performance:

- Tooth Profile: The tooth profile of the helical gear rack significantly influences its performance. The shape and dimensions of the teeth determine factors such as load distribution, contact ratio, smoothness of engagement, and noise generation. An optimized tooth profile ensures efficient power transmission, minimizes stress concentrations, and reduces noise and vibration levels. The choice of tooth profile, such as involute, leads to different performance characteristics and can be tailored to specific application requirements.

- Pressure Angle: The pressure angle is the angle between the line of action and a line perpendicular to the tooth surface. It affects the load-carrying capacity and efficiency of the gear rack. Higher pressure angles, such as 20 degrees or 25 degrees, provide higher load capacity but may result in lower efficiency due to increased sliding friction. Lower pressure angles, such as 14.5 degrees, offer improved efficiency but have a reduced load capacity. The selection of the pressure angle depends on the specific application’s requirements regarding load capacity, efficiency, and noise considerations.

- Helix Angle: The helix angle refers to the angle between the tooth and the gear rack’s axis. Helical gear racks have teeth that are cut at an angle, resulting in a helical shape. The helix angle affects the smoothness of tooth engagement and the distribution of forces along the tooth surface. A higher helix angle typically provides smoother and quieter operation but may reduce the gear rack’s load capacity. The selection of the helix angle depends on the desired balance between performance, noise level, and load capacity for a specific application.

- Module: The module, also known as the diametral pitch, defines the size and spacing of the teeth on the gear rack. It affects the gear rack’s load capacity, strength, and the size of the mating gear. A larger module typically results in stronger teeth and higher load-carrying capacity. However, it may also require larger mating gears and increase the overall size of the gear system. The module is selected based on the specific application requirements, considering factors such as load, speed, space constraints, and desired gear system efficiency.

- Material: The choice of material for the helical gear rack affects its performance and durability. Common materials used for gear racks include steel, stainless steel, cast iron, and various alloys. The material should have sufficient strength, hardness, and wear resistance to withstand the anticipated loads and operating conditions. The material selection also considers factors such as corrosion resistance, cost, and availability. Proper material selection ensures that the gear rack can perform reliably and maintain its integrity throughout its service life.

- Manufacturing Quality: The manufacturing quality of the helical gear rack is crucial for its performance. Precise machining and manufacturing processes ensure accurate tooth profiles, correct dimensions, and proper alignment of the gear rack. Good manufacturing practices help in achieving smooth tooth engagement, minimizing backlash, and ensuring consistent performance. High-quality manufacturing also reduces the risk of premature wear, tooth failure, and system inefficiencies.

It’s important to note that the specific design parameters and their impact on performance may vary depending on the application requirements, load conditions, and the overall gear system design. Consulting with gear rack specialists or manufacturers can help in selecting the appropriate design parameters to optimize the gear rack’s performance for a specific application.

In summary, the design of the helical gear rack, including the tooth profile, pressure angle, helix angle, module, material, and manufacturing quality, significantly affects its performance. The design parameters influence load capacity, efficiency, noise level, smoothness of engagement, strength, and overall reliability. A well-designed gear rack ensures efficient power transmission, minimal wear, and reliable performance in a wide range of applications.

How do helical gear racks contribute to efficient power transmission?

Helical gear racks play a significant role in achieving efficient power transmission in mechanical systems. They offer several design features and characteristics that contribute to the efficient transfer of power. Here’s a detailed explanation:

- Tooth Engagement: Helical gear racks provide continuous contact between the gear teeth during operation. Unlike spur gear racks, which have a straight tooth profile, helical gear racks have teeth that are cut at an angle (helix angle) to the gear axis. This angled tooth profile enables gradual and smooth engagement with the mating helical gear, reducing the impact of sudden contact and minimizing noise and vibration. The continuous tooth engagement ensures a larger contact area between the gear rack and gear, leading to improved load distribution and power transmission efficiency.

- Load Distribution: The helical tooth profile of gear racks allows for load distribution across multiple teeth. As the gear rotates, the inclined teeth of the gear mesh with the helical gear rack, and the load is shared among several teeth simultaneously. This distributed load-carrying capability helps reduce stress on individual teeth, minimizing the risk of tooth wear, fatigue, and potential failure. By distributing the load, helical gear racks can handle higher torque and transmit power more efficiently.

- Reduced Sliding Friction: The helical tooth profile also contributes to reducing sliding friction between the gear teeth. As the helical gear rotates, the inclined teeth smoothly slide against the mating gear rack’s teeth. This sliding action helps distribute the lubricating film across a larger contact area, minimizing frictional losses and heat generation. The reduced sliding friction improves the mechanical efficiency of the gear system, allowing for more effective power transmission.

- Backlash Reduction: Backlash refers to the clearance or lost motion between the gear teeth when changing direction. Helical gear racks help reduce backlash compared to other gear types, such as spur gear racks. The inclined teeth of helical gear racks engage gradually with the mating gear, resulting in a smoother and tighter meshing. This reduced backlash improves the accuracy and responsiveness of the power transmission system, contributing to overall efficiency.

- Choice of Materials and Lubrication: The choice of materials for helical gear racks, as well as proper lubrication, also play a role in efficient power transmission. High-quality materials with good wear resistance and strength ensure minimal energy losses due to friction and wear. Additionally, proper lubrication helps reduce friction, dissipate heat, and protect against excessive wear, enhancing the overall efficiency and durability of the gear system.

By incorporating these design features and characteristics, helical gear racks contribute to efficient power transmission by reducing noise and vibration, improving load distribution, minimizing sliding friction and backlash, and ensuring proper lubrication. These factors collectively enhance the mechanical efficiency of the gear system, enabling effective power transfer in various applications.

How does a helical gear rack differ from other types of gear racks?

A helical gear rack differs from other types of gear racks in several key aspects. Here’s a detailed explanation of the differences between a helical gear rack and other types of gear racks:

1. Tooth Orientation:

- Straight Gear Rack: A straight gear rack has teeth that are cut perpendicular to the rack’s axis. The teeth are straight and parallel to the rack’s length.

- Helical Gear Rack: A helical gear rack has teeth that are cut at an angle or helix to the rack’s axis. The teeth have a helical shape, similar to the teeth of a helical gear.

- Spiral Gear Rack: A spiral gear rack combines the characteristics of both straight and helical gear racks. It has teeth that are cut at an angle to the rack’s axis, but the angle changes gradually along the length of the rack, creating a spiral shape.

2. Smoothness and Noise:

- Straight Gear Rack: Straight gear racks tend to produce more noise and vibration during operation due to the instantaneous contact between the gear teeth and the rack teeth.

- Helical Gear Rack: Helical gear racks provide smoother operation and reduced noise compared to straight gear racks. The helical teeth gradually engage, resulting in a smoother meshing action and quieter operation.

- Spiral Gear Rack: Spiral gear racks also offer smoother operation and reduced noise levels due to the gradual engagement of the teeth along the spiral path.

3. Load Distribution:

- Straight Gear Rack: In a straight gear rack, only a limited number of teeth engage with the mating gear at any given time, resulting in localized load distribution on the teeth.

- Helical Gear Rack: Helical gear racks provide improved load distribution compared to straight gear racks. The angled teeth allow multiple teeth to be in contact simultaneously, distributing the load across a larger area and reducing tooth stress.

- Spiral Gear Rack: Similar to helical gear racks, spiral gear racks also offer improved load distribution due to the angled teeth and the changing spiral angle along the rack’s length.

4. Application:

- Straight Gear Rack: Straight gear racks are commonly used in applications where linear motion needs to be achieved without the need for smoothness or reduced noise. They are simpler in design and suitable for applications with lower precision requirements.

- Helical Gear Rack: Helical gear racks are preferred in applications that require smoother operation, reduced noise, and improved load distribution. They are commonly used in precision machinery, such as CNC machines, where precise linear positioning is essential.

- Spiral Gear Rack: Spiral gear racks are utilized in applications that require smooth operation and load distribution, similar to helical gear racks. They are often found in automation systems, robotics, and other motion control applications.

In summary, a helical gear rack differs from other types of gear racks in terms of tooth orientation, smoothness, noise, load distribution, and application. The helical gear rack’s angled teeth provide smoother operation, reduced noise, and improved load distribution compared to straight gear racks. Spiral gear racks combine the characteristics of both straight and helical gear racks, offering gradual tooth engagement along a spiral path. The choice of gear rack type depends on the specific requirements of the application, such as precision, smoothness, noise levels, and load distribution needs.

editor by Dream 2024-04-29