Product Description

Product Description

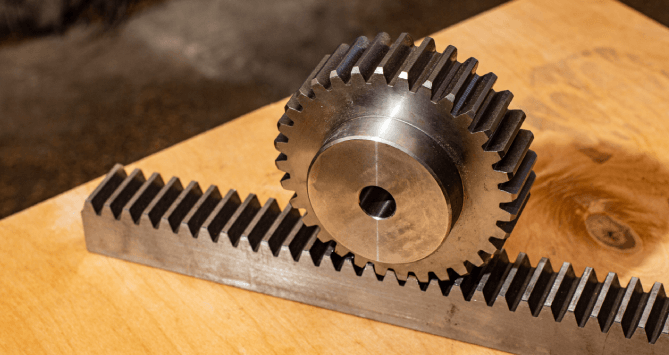

We manufacture different types of gear rack as follows:

1. Module: M0.5, M1, M1.5, M2, M2.5, M3, M4, M5, M6, M8, etc; Diametral Pitch: 24DP, 48DP, etc.

2. Length: 500, 1000mm, 2000mm, 2500mm, 3000mm, etc.

3. Shape: round, square; Teeth type: straight, spur, helical.

4. Material Choice: plastic, aluminum, nylon, steel, stainless steel, cast iron, copper, brass.

5. Surface Finish: anodize, phosphate, black oxide, zinc plate, paint, passivate, etc.

Mainly used in the mining, metallurgical, cement, chemicals,construction, buiding materials,

electric power, telecommunictions, textiles, and transportation departments.

Such as:

1. conveyor:Belt conveyor,AFC conveyor, chain conveyor, screw conveyor.

2. Pum:Water pump, oil pump, slush pump, etc.

3. Fan: Draft fan, fanner, boil fan, etc.

4. Excator:bucket excavator bucket, wheel excavators .

5. Crane:Tower crane, gantry crande, bridge crane.

6. Others:Various elevators, coal plough, ball mill, crusher, recreation machine.

7. Blender equipment, centrifuger, washer, leather-making machine, machine for recreation park mixer wire drawing machine.Extruder, dregs crusher of boiler.

8. Plastic feeder, rubber smelling machine, etc.

Detailed Photos

Product Parameters

Packaging & Shipping

| Package | Standard suitable package / Pallet or container. Polybag inside export carton outside, blister and Tape and reel package available. If customers have specific requirements for the packaging, we will gladly accommodate |

| Shipping |

10-20working days ofter payment receipt comfirmed (based on actual quantity). Professional goods shipping forward. |

Company Profile

FAQ

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit. To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Helical Gear |

| Material: | Steel C45/Nylon/40cr/Copper |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do helical gear racks handle different gear ratios and helix angles?

Helical gear racks are designed to handle different gear ratios and helix angles, providing flexibility in power transmission systems. The gear ratio determines the speed and torque conversion between the driving and driven gears, while the helix angle influences the smoothness of engagement and the load distribution across the gear teeth. Here’s a detailed explanation of how helical gear racks handle these parameters:

- Gear Ratios: Helical gear racks can accommodate different gear ratios by pairing them with helical gears of corresponding ratios. The gear ratio is determined by the number of teeth on the driving and driven gears. By selecting helical gears with different numbers of teeth, the gear ratio can be adjusted to achieve the desired speed and torque conversion. Helical gear racks provide a linear motion that engages with the helical gear, allowing for precise and efficient power transmission across a wide range of gear ratios.

- Helix Angles: The helix angle is the angle at which the gear teeth are inclined relative to the gear axis. Helical gear racks are designed with a corresponding helix angle that matches the helix angle of the mating helical gear. The helix angle affects the smoothness of engagement and the load distribution across the gear teeth. A larger helix angle results in a smoother and quieter operation, as it facilitates gradual tooth contact during meshing. It also helps distribute the load across multiple teeth, reducing the stress on individual teeth and promoting higher load-carrying capacity.

When handling different gear ratios and helix angles, it’s important to consider the following factors:

- Tooth Contact: As the gear ratio and helix angle change, the contact pattern between the helical gear and gear rack may shift. Proper tooth contact is crucial for efficient power transmission and to avoid excessive wear or noise. It’s essential to ensure that the gear rack and helical gear are properly aligned and adjusted to achieve the desired tooth contact pattern.

- Lubrication: Adequate lubrication is vital to reduce friction and wear between the gear teeth. The presence of a helix angle introduces sliding motion between the helical gear and gear rack during engagement. Proper lubrication helps minimize frictional losses and ensures smooth operation even at higher helix angles or gear ratios.

- Load Distribution: The helix angle and gear ratio affect the load distribution across the gear teeth. Higher helix angles and gear ratios can distribute the load more evenly, reducing the stress on individual teeth and promoting higher load-carrying capacity. This is particularly advantageous in applications with high torque or heavy loads.

It’s important to note that as the gear ratio increases or the helix angle becomes steeper, the axial forces on the gear rack also increase. Adequate support and proper mounting arrangements are necessary to handle these axial forces and ensure the gear rack remains stable and properly engaged with the helical gear.

In summary, helical gear racks handle different gear ratios and helix angles by providing a linear motion that engages with helical gears of corresponding ratios and angles. Through proper tooth contact, lubrication, and load distribution, helical gear racks enable efficient power transmission and smooth operation across a wide range of gear ratios and helix angles in various applications.

Can helical gear racks be integrated into robotic and automation equipment?

Yes, helical gear racks can be effectively integrated into robotic and automation equipment, offering several advantages in terms of motion control, precision, and efficiency. Here’s a detailed explanation:

- Precision and Accuracy: Helical gear racks provide precise and accurate linear motion, making them well-suited for robotic and automation applications that require controlled and repeatable movements. The inclined teeth of the gear rack engage with the mating helical gear, ensuring smooth and continuous motion with minimal backlash. This level of precision is crucial for tasks such as positioning, pick-and-place operations, and assembly tasks in robotics and automation.

- Load Capacity: Helical gear racks are capable of handling significant loads. Their design allows for load distribution across multiple teeth, reducing stress concentration and increasing the load-carrying capacity. This makes them suitable for applications that involve moving heavy objects or performing tasks that require high torque.

- Efficient Power Transmission: The helical tooth profile and continuous tooth engagement of gear racks contribute to efficient power transmission. The inclined teeth enable smooth meshing with the helical gear, reducing noise, vibration, and energy losses due to friction. The load distribution across multiple teeth helps minimize wear and increases the overall efficiency of the power transmission system in robotic and automation equipment.

- Compact Design: Helical gear racks have a compact design, which is advantageous in space-constrained robotic and automation systems. Their linear motion capability allows for more streamlined and efficient mechanical arrangements, making them suitable for applications where space optimization is essential.

- Compatibility with Drive Systems: Helical gear racks can be easily integrated with various drive systems commonly used in robotics and automation, such as servo motors, stepper motors, or linear actuators. They can be mounted and coupled with these drive systems to convert rotary motion into linear motion or vice versa, enabling precise control over the movement of robotic arms, gantries, or other automated mechanisms.

- Reliability and Durability: Helical gear racks are known for their durability and long service life. They are designed to withstand high loads, provide smooth motion, and resist wear and fatigue. This reliability is crucial in robotic and automation equipment, where consistent and uninterrupted operation is required.

Considering these benefits, helical gear racks find wide applications in various robotic and automation equipment, including industrial robots, CNC machines, automated assembly lines, and material handling systems. Their integration enhances the performance, precision, and efficiency of these systems, contributing to increased productivity and improved overall automation processes.

How do helical gear racks handle variations in load capacity and speed?

Helical gear racks are designed to handle variations in load capacity and speed efficiently. Here’s a detailed explanation of how helical gear racks accommodate these variations:

Load Capacity:

Helical gear racks are known for their excellent load-carrying capacity. The helical tooth design allows for multiple teeth to be engaged simultaneously, resulting in a larger contact area and improved load distribution. This distributed load sharing minimizes stress concentrations on individual teeth and increases the overall load capacity of the gear rack system. As a result, helical gear racks can handle higher loads compared to straight gear racks.

Furthermore, the tooth profile of helical gear racks is typically optimized to provide maximum strength and contact area. This ensures that the gear rack can withstand the forces exerted by the load without experiencing premature wear or failure. Manufacturers may also use high-strength materials and heat treatment processes to enhance the load capacity of helical gear racks.

Speed:

Helical gear racks can handle variations in speed effectively. The helical tooth design enables smooth and gradual engagement between the rack and the mating gear. This gradual engagement reduces impact and minimizes the risk of sudden speed changes that could lead to shock loads or vibrations. The gradual engagement also helps in reducing noise and enhancing the overall operation of the gear rack system.

In addition, the tooth profile of helical gear racks is designed to optimize the contact ratio between the rack and the mating gear. A higher contact ratio means that multiple teeth are in contact at any given time, distributing the load and minimizing the pressure on individual teeth. This helps in reducing wear and ensuring the gear rack can handle variations in speed without compromising its performance or longevity.

It’s worth noting that the specific load capacity and speed capabilities of a helical gear rack depend on various factors such as the design, material, tooth profile, manufacturing quality, and lubrication. It’s essential to consider these factors and consult the manufacturer’s specifications to ensure the gear rack is appropriately selected and operated within its recommended limits.

In summary, helical gear racks handle variations in load capacity by distributing the load across multiple teeth, minimizing stress concentrations, and optimizing the tooth profile for strength. They handle variations in speed by providing smooth and gradual tooth engagement, reducing impact and vibrations. These characteristics make helical gear racks capable of efficiently accommodating variations in load capacity and speed in a wide range of applications.

editor by CX 2023-09-25