Product Description

Product Description

|

Products |

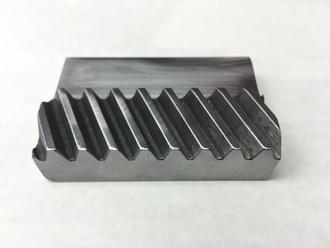

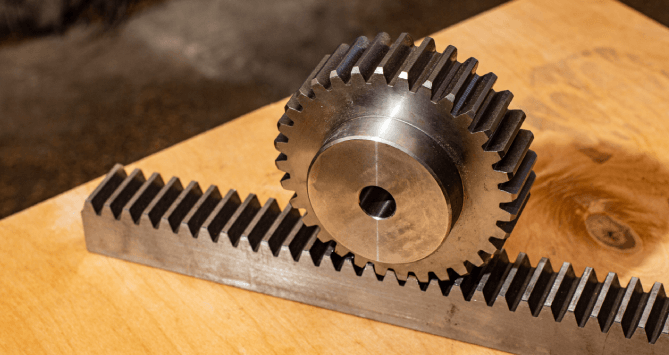

Gear rack |

|||

|

Precision grade |

DIN5, DIN6, DIN7, DIN8, DIN10 |

|||

|

Material |

C45 steel, 304SS, 316SS, 40CrMo, nylon, POM |

|||

|

Heat treatment |

High frequency,Quenching/Carburization, Teeth hardened |

|||

|

Surface treatment |

Zinc-plated,Nickle-plated,Chrome-plated,Black oxide or as you need |

|||

|

Application Machine |

Precision cutting machines. Lathes machine Milling machines Grinders machine Automated mechanical systems Automated warehousing systems. |

|||

|

Produce Machine |

CNC engine lathe CNC milling machine CNC drilling machine CNC grinding machine CNC cutting machines Machining center |

|||

|

Workstyle |

Execution is more preferred than empty talk. |

|||

|

Stock Gear Rack Type |

Specification |

Color |

|

Helical gear rack |

M1 15*15*1000mm |

White |

|

M1.5 19*19*1000mm |

White |

|

|

M2 24*24*1000mm |

White |

|

|

M3 29*29*1000mm |

White |

|

|

M4 39x39x1000mm |

White |

|

|

Spur gear rak |

M1 15*15*1000mm |

Black |

Rack Assembly

To assemble connected racks more smoothly, 2 ends of a standard rack would add half tooth which is convenient for next half tooth of next rack to be connected to a complete tooth. The following drawing shows how 2 racks connect and tooth gauge can control pitch position accurately.

With regards to connection of helical racks, it can be connected accurately by opposite tooth gauge.

1. When connecting racks, we recommend lock bores on the sides of rack first, and lock bores by the sequence of the foundation. With assembling the tooth gauge, pitch position of racks can be assembled accurately and completely.

2. Last, lock the position pins on 2 sides of rack; the assembly is completed.

Test

Use Coordinate Measuring Machine to test the precision and hardness of gear rack and pinion

Packaging & Shipping

Small quantity: We will use carton box.

Big quantity: We will use wooden cases.

Company Profile

ZheJiang Haorongshengye Electrical Equipment Co., Ltd.

1. Was founded in 2008

2. Our Principle:

“Credibility Supremacy, and Customer First”

3. Our Promise:

“High quality products, and Excellent Service”

4. Our Value:

“Being Honesty, Doing the Best, and Long-lasting Development”

5. Our Aim:

“Develop to be a leader in the power transmission parts industry in the world”

|

6.Our services: |

1).Competitive price |

|||

|

2).High quality products |

||||

|

3).OEM service or can customized according to your drawings |

||||

|

4).Reply your inquiry in 24 hours |

||||

|

5).Professional technical team 24 hours online service |

||||

|

6).Provide sample service |

||||

Main products

Machines

Exbihition

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Hobbing |

| Toothed Portion Shape: | Spur Gear |

| Material: | Steel |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do helical gear racks handle different gear ratios and helix angles?

Helical gear racks are designed to handle different gear ratios and helix angles, providing flexibility in power transmission systems. The gear ratio determines the speed and torque conversion between the driving and driven gears, while the helix angle influences the smoothness of engagement and the load distribution across the gear teeth. Here’s a detailed explanation of how helical gear racks handle these parameters:

- Gear Ratios: Helical gear racks can accommodate different gear ratios by pairing them with helical gears of corresponding ratios. The gear ratio is determined by the number of teeth on the driving and driven gears. By selecting helical gears with different numbers of teeth, the gear ratio can be adjusted to achieve the desired speed and torque conversion. Helical gear racks provide a linear motion that engages with the helical gear, allowing for precise and efficient power transmission across a wide range of gear ratios.

- Helix Angles: The helix angle is the angle at which the gear teeth are inclined relative to the gear axis. Helical gear racks are designed with a corresponding helix angle that matches the helix angle of the mating helical gear. The helix angle affects the smoothness of engagement and the load distribution across the gear teeth. A larger helix angle results in a smoother and quieter operation, as it facilitates gradual tooth contact during meshing. It also helps distribute the load across multiple teeth, reducing the stress on individual teeth and promoting higher load-carrying capacity.

When handling different gear ratios and helix angles, it’s important to consider the following factors:

- Tooth Contact: As the gear ratio and helix angle change, the contact pattern between the helical gear and gear rack may shift. Proper tooth contact is crucial for efficient power transmission and to avoid excessive wear or noise. It’s essential to ensure that the gear rack and helical gear are properly aligned and adjusted to achieve the desired tooth contact pattern.

- Lubrication: Adequate lubrication is vital to reduce friction and wear between the gear teeth. The presence of a helix angle introduces sliding motion between the helical gear and gear rack during engagement. Proper lubrication helps minimize frictional losses and ensures smooth operation even at higher helix angles or gear ratios.

- Load Distribution: The helix angle and gear ratio affect the load distribution across the gear teeth. Higher helix angles and gear ratios can distribute the load more evenly, reducing the stress on individual teeth and promoting higher load-carrying capacity. This is particularly advantageous in applications with high torque or heavy loads.

It’s important to note that as the gear ratio increases or the helix angle becomes steeper, the axial forces on the gear rack also increase. Adequate support and proper mounting arrangements are necessary to handle these axial forces and ensure the gear rack remains stable and properly engaged with the helical gear.

In summary, helical gear racks handle different gear ratios and helix angles by providing a linear motion that engages with helical gears of corresponding ratios and angles. Through proper tooth contact, lubrication, and load distribution, helical gear racks enable efficient power transmission and smooth operation across a wide range of gear ratios and helix angles in various applications.

How do helical gear racks contribute to efficient power transmission?

Helical gear racks play a significant role in achieving efficient power transmission in mechanical systems. They offer several design features and characteristics that contribute to the efficient transfer of power. Here’s a detailed explanation:

- Tooth Engagement: Helical gear racks provide continuous contact between the gear teeth during operation. Unlike spur gear racks, which have a straight tooth profile, helical gear racks have teeth that are cut at an angle (helix angle) to the gear axis. This angled tooth profile enables gradual and smooth engagement with the mating helical gear, reducing the impact of sudden contact and minimizing noise and vibration. The continuous tooth engagement ensures a larger contact area between the gear rack and gear, leading to improved load distribution and power transmission efficiency.

- Load Distribution: The helical tooth profile of gear racks allows for load distribution across multiple teeth. As the gear rotates, the inclined teeth of the gear mesh with the helical gear rack, and the load is shared among several teeth simultaneously. This distributed load-carrying capability helps reduce stress on individual teeth, minimizing the risk of tooth wear, fatigue, and potential failure. By distributing the load, helical gear racks can handle higher torque and transmit power more efficiently.

- Reduced Sliding Friction: The helical tooth profile also contributes to reducing sliding friction between the gear teeth. As the helical gear rotates, the inclined teeth smoothly slide against the mating gear rack’s teeth. This sliding action helps distribute the lubricating film across a larger contact area, minimizing frictional losses and heat generation. The reduced sliding friction improves the mechanical efficiency of the gear system, allowing for more effective power transmission.

- Backlash Reduction: Backlash refers to the clearance or lost motion between the gear teeth when changing direction. Helical gear racks help reduce backlash compared to other gear types, such as spur gear racks. The inclined teeth of helical gear racks engage gradually with the mating gear, resulting in a smoother and tighter meshing. This reduced backlash improves the accuracy and responsiveness of the power transmission system, contributing to overall efficiency.

- Choice of Materials and Lubrication: The choice of materials for helical gear racks, as well as proper lubrication, also play a role in efficient power transmission. High-quality materials with good wear resistance and strength ensure minimal energy losses due to friction and wear. Additionally, proper lubrication helps reduce friction, dissipate heat, and protect against excessive wear, enhancing the overall efficiency and durability of the gear system.

By incorporating these design features and characteristics, helical gear racks contribute to efficient power transmission by reducing noise and vibration, improving load distribution, minimizing sliding friction and backlash, and ensuring proper lubrication. These factors collectively enhance the mechanical efficiency of the gear system, enabling effective power transfer in various applications.

How do helical gear racks handle variations in load capacity and speed?

Helical gear racks are designed to handle variations in load capacity and speed efficiently. Here’s a detailed explanation of how helical gear racks accommodate these variations:

Load Capacity:

Helical gear racks are known for their excellent load-carrying capacity. The helical tooth design allows for multiple teeth to be engaged simultaneously, resulting in a larger contact area and improved load distribution. This distributed load sharing minimizes stress concentrations on individual teeth and increases the overall load capacity of the gear rack system. As a result, helical gear racks can handle higher loads compared to straight gear racks.

Furthermore, the tooth profile of helical gear racks is typically optimized to provide maximum strength and contact area. This ensures that the gear rack can withstand the forces exerted by the load without experiencing premature wear or failure. Manufacturers may also use high-strength materials and heat treatment processes to enhance the load capacity of helical gear racks.

Speed:

Helical gear racks can handle variations in speed effectively. The helical tooth design enables smooth and gradual engagement between the rack and the mating gear. This gradual engagement reduces impact and minimizes the risk of sudden speed changes that could lead to shock loads or vibrations. The gradual engagement also helps in reducing noise and enhancing the overall operation of the gear rack system.

In addition, the tooth profile of helical gear racks is designed to optimize the contact ratio between the rack and the mating gear. A higher contact ratio means that multiple teeth are in contact at any given time, distributing the load and minimizing the pressure on individual teeth. This helps in reducing wear and ensuring the gear rack can handle variations in speed without compromising its performance or longevity.

It’s worth noting that the specific load capacity and speed capabilities of a helical gear rack depend on various factors such as the design, material, tooth profile, manufacturing quality, and lubrication. It’s essential to consider these factors and consult the manufacturer’s specifications to ensure the gear rack is appropriately selected and operated within its recommended limits.

In summary, helical gear racks handle variations in load capacity by distributing the load across multiple teeth, minimizing stress concentrations, and optimizing the tooth profile for strength. They handle variations in speed by providing smooth and gradual tooth engagement, reducing impact and vibrations. These characteristics make helical gear racks capable of efficiently accommodating variations in load capacity and speed in a wide range of applications.

editor by CX 2023-10-07