Product Description

Product Description

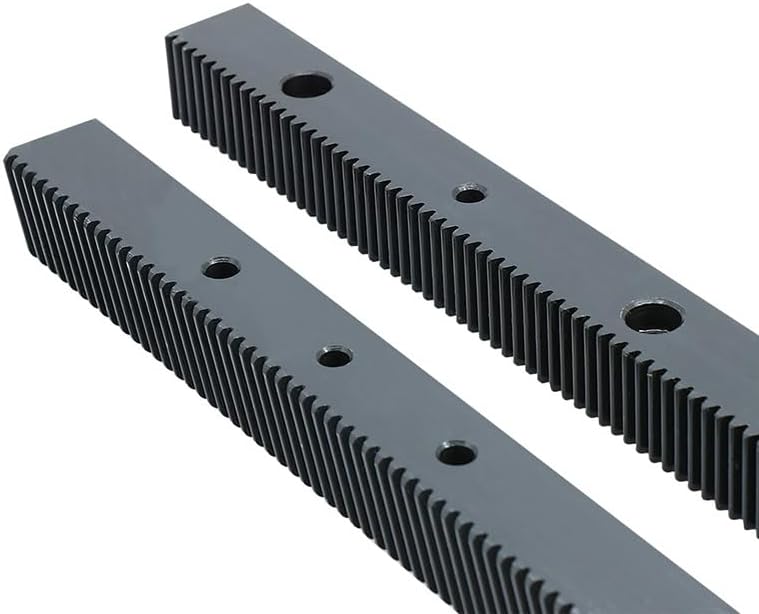

We manufacture different types of gear rack as follows:

1. Module: M0.5, M1, M1.5, M2, M2.5, M3, M4, M5, M6, M8, etc; Diametral Pitch: 24DP, 48DP, etc.

2. Length: 500, 1000mm, 2000mm, 2500mm, 3000mm, etc.

3. Shape: round, square; Teeth type: straight, spur, helical.

4. Material Choice: plastic, aluminum, nylon, steel, stainless steel, cast iron, copper, brass.

5. Surface Finish: anodize, phosphate, black oxide, zinc plate, paint, passivate, etc.

Mainly used in the mining, metallurgical, cement, chemicals,construction, buiding materials,

electric power, telecommunictions, textiles, and transportation departments.

Such as:

1. conveyor:Belt conveyor,AFC conveyor, chain conveyor, screw conveyor.

2. Pum:Water pump, oil pump, slush pump, etc.

3. Fan: Draft fan, fanner, boil fan, etc.

4. Excator:bucket excavator bucket, wheel excavators .

5. Crane:Tower crane, gantry crande, bridge crane.

6. Others:Various elevators, coal plough, ball mill, crusher, recreation machine.

7. Blender equipment, centrifuger, washer, leather-making machine, machine for recreation park mixer wire drawing machine.Extruder, dregs crusher of boiler.

8. Plastic feeder, rubber smelling machine, etc.

Detailed Photos

Product Parameters

Packaging & Shipping

| Package | Standard suitable package / Pallet or container. Polybag inside export carton outside, blister and Tape and reel package available. If customers have specific requirements for the packaging, we will gladly accommodate |

| Shipping |

10-20working days ofter payment receipt comfirmed (based on actual quantity). Professional goods shipping forward. |

Company Profile

FAQ

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit. To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Helical Gear |

| Material: | Steel C45/Nylon/40cr/Copper |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What safety considerations should be kept in mind when working with helical gear racks?

When working with helical gear racks, it is essential to keep several safety considerations in mind. Here’s a detailed explanation of the safety considerations associated with helical gear racks:

- Proper Training: Individuals working with helical gear racks should receive proper training on their installation, operation, and maintenance. This training should cover safety procedures, potential hazards, and the correct use of personal protective equipment (PPE).

- Pinch Points: Helical gear racks typically have teeth that can create pinch points during operation. It is crucial to exercise caution and avoid placing fingers, hands, or any body part near the gear rack while it is in motion. Adequate guarding or barriers should be in place to prevent accidental contact with moving parts.

- Lubrication: Proper lubrication is essential for the smooth operation and longevity of helical gear racks. However, spilled or excess lubricant can create slippery surfaces, increasing the risk of slips, trips, and falls. Adequate housekeeping measures should be in place to clean up any spills promptly and maintain a safe working environment.

- Overloading and Shock Loads: Helical gear racks have specified load capacities that should not be exceeded. Overloading the gear rack or subjecting it to sudden shock loads can lead to premature wear, tooth failure, or even catastrophic system failure. It is important to adhere to the manufacturer’s recommended load limits and avoid sudden or excessive loading.

- Maintenance and Inspection: Regular maintenance and inspection of helical gear racks are crucial for identifying any signs of wear, damage, or misalignment. Worn or damaged gear racks should be promptly replaced to prevent potential failures. Routine inspections should also include checking for proper lubrication, tightness of fasteners, and overall condition of the gear rack system.

- Electrical Hazards: In applications where helical gear racks are driven by electric motors or other power sources, electrical hazards may be present. Proper electrical safety measures, such as grounding, insulation, and lockout/tagout procedures, should be followed to prevent electrical shocks or accidents.

- Workplace Ergonomics: Consideration should be given to the ergonomics of the work environment to minimize the risk of strain or injury. This may include ensuring proper lighting, clear visibility of the gear rack area, and ergonomic positioning of controls or workstations.

- Personal Protective Equipment (PPE): Depending on the specific workplace hazards associated with helical gear racks, appropriate personal protective equipment (PPE) should be worn. This may include safety glasses, protective gloves, hearing protection, and safety footwear to mitigate the risk of injury.

It is important to consult relevant safety guidelines, regulations, and the manufacturer’s instructions specific to the helical gear rack being used. Following proper safety practices and maintaining a safe working environment helps reduce the risk of accidents, injuries, and equipment damage when working with helical gear racks.

Can helical gear racks be applied in CNC machining for positioning?

Yes, helical gear racks can be effectively applied in CNC (Computer Numerical Control) machining for precise positioning. Here’s a detailed explanation:

- Precision Positioning: CNC machining requires accurate and repeatable positioning of the cutting tool or workpiece. Helical gear racks offer precise linear motion, making them well-suited for CNC applications that require precise positioning along the X, Y, or Z-axis. The inclined teeth of the gear rack engage with the mating helical gear, ensuring smooth and continuous motion with minimal backlash. This precision positioning capability enables CNC machines to achieve the desired accuracy in cutting, drilling, milling, and other machining operations.

- Load Capacity: CNC machining often involves heavy workpieces and cutting forces. Helical gear racks are designed to handle significant loads. The load distribution across multiple teeth reduces stress concentration and increases the load-carrying capacity of the gear rack. This makes helical gear racks suitable for CNC applications that involve moving heavy workpieces or applying high cutting forces, ensuring stable and reliable positioning during machining processes.

- Smooth Motion and Reduced Vibration: The inclined tooth profile of helical gear racks enables smooth and continuous motion. The gradual engagement of the teeth with the mating gear results in reduced noise, vibration, and sudden impacts compared to other gear types. This smooth motion and reduced vibration contribute to improved surface finish, dimensional accuracy, and tool life in CNC machining. It helps minimize chatter and tool deflection, allowing for precise and efficient material removal during the machining process.

- Compatibility with CNC Systems: Helical gear racks can be easily integrated into CNC systems. They can be coupled with servo motors or linear actuators and incorporated into the machine’s mechanical structure to convert rotary motion into linear motion. CNC control systems can accurately control the movement of the gear rack, enabling precise positioning based on the programmed instructions. The compatibility of helical gear racks with various CNC systems makes them a reliable and versatile choice for achieving precise positioning in CNC machining.

- High Durability and Long Service Life: Helical gear racks are known for their durability and long service life. They are designed to withstand high loads, provide smooth motion, and resist wear and fatigue. In CNC machining, where machines often operate for extended periods, the reliability and longevity of gear racks are crucial. The robust construction and quality manufacturing of helical gear racks ensure their ability to withstand the demanding conditions of CNC machining environments.

Considering these advantages, helical gear racks are widely used in CNC machining for accurate and reliable positioning. Their precision, load capacity, smooth motion, compatibility with CNC systems, and durability make them suitable for a variety of CNC applications, including milling, turning, grinding, and other machining operations. By incorporating helical gear racks into CNC machines, manufacturers can achieve the desired precision, productivity, and quality in their machining processes.

In which industries are helical gear racks commonly used?

Helical gear racks are commonly used in various industries that require precise linear motion control and reliable power transmission. Here’s a detailed explanation of the industries where helical gear racks are commonly employed:

- Manufacturing Industry: Helical gear racks find extensive use in the manufacturing industry. They are employed in machinery and equipment used for metalworking, woodworking, plastics processing, and other manufacturing processes. Helical gear racks enable precise linear motion control in machine tools, automation systems, conveyors, and other manufacturing equipment.

- Automotive Industry: The automotive industry relies on helical gear racks for various applications. They are used in production lines for vehicle assembly, robotic systems for welding and painting, and automated storage and retrieval systems. Helical gear racks provide accurate linear positioning and smooth motion control in automotive manufacturing processes.

- Aerospace Industry: Helical gear racks play a critical role in the aerospace industry. They are utilized in the production of aircraft components, including wing structures, landing gear systems, and control surfaces. The precise linear motion provided by helical gear racks ensures the accuracy and reliability of aerospace systems.

- Robotics and Automation Industry: The robotics and automation industry extensively uses helical gear racks. They are employed in industrial robots, collaborative robots (cobots), automated guided vehicles (AGVs), and other robotic systems. Helical gear racks contribute to the precise and controlled linear motion required for pick-and-place operations, assembly tasks, and material handling in robotic and automation applications.

- Printing and Packaging Industry: Helical gear racks are commonly found in printing and packaging machinery. They provide accurate linear motion control in printing presses, packaging equipment, labeling machines, and other related systems. Helical gear racks ensure precise registration, consistent print quality, and reliable packaging operations.

- Textile Industry: In the textile industry, helical gear racks are used in various textile manufacturing machines such as looms, knitting machines, and textile printing systems. They enable controlled linear motion for the weaving, knitting, and printing processes, ensuring accurate fabric production and pattern alignment.

- Medical and Healthcare Industry: Helical gear racks find applications in the medical and healthcare industry. They are used in medical equipment such as imaging systems, diagnostic devices, robotic surgical systems, and rehabilitation equipment. Helical gear racks contribute to precise linear motion control in these medical applications, enhancing the accuracy and reliability of diagnostic and treatment processes.

These are just a few examples of the industries where helical gear racks are commonly used. Their ability to provide smooth, precise, and reliable linear motion control makes them a valuable component in a wide range of industries that require accurate positioning, synchronization, and power transmission.

editor by CX 2023-11-10